About Us

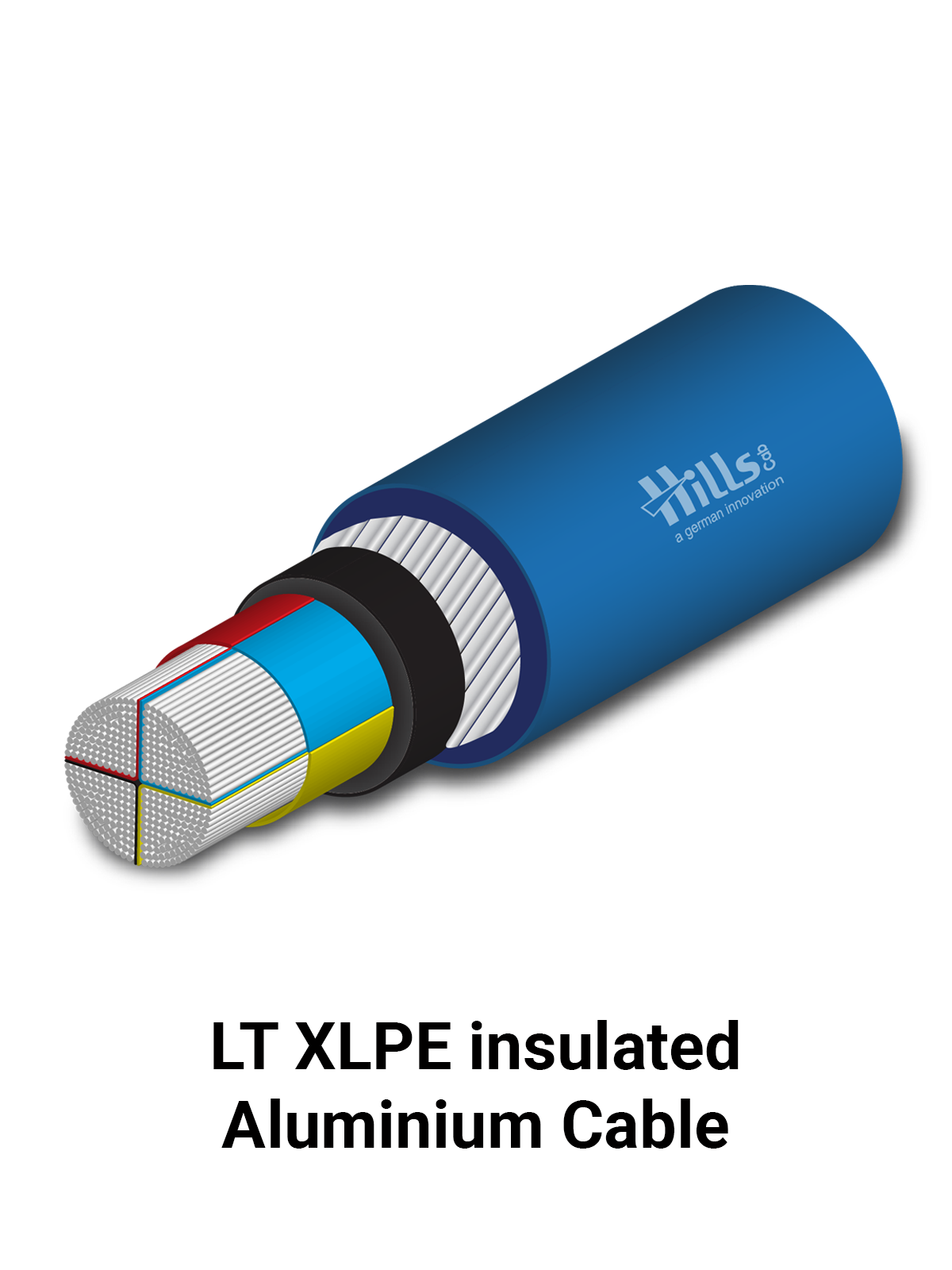

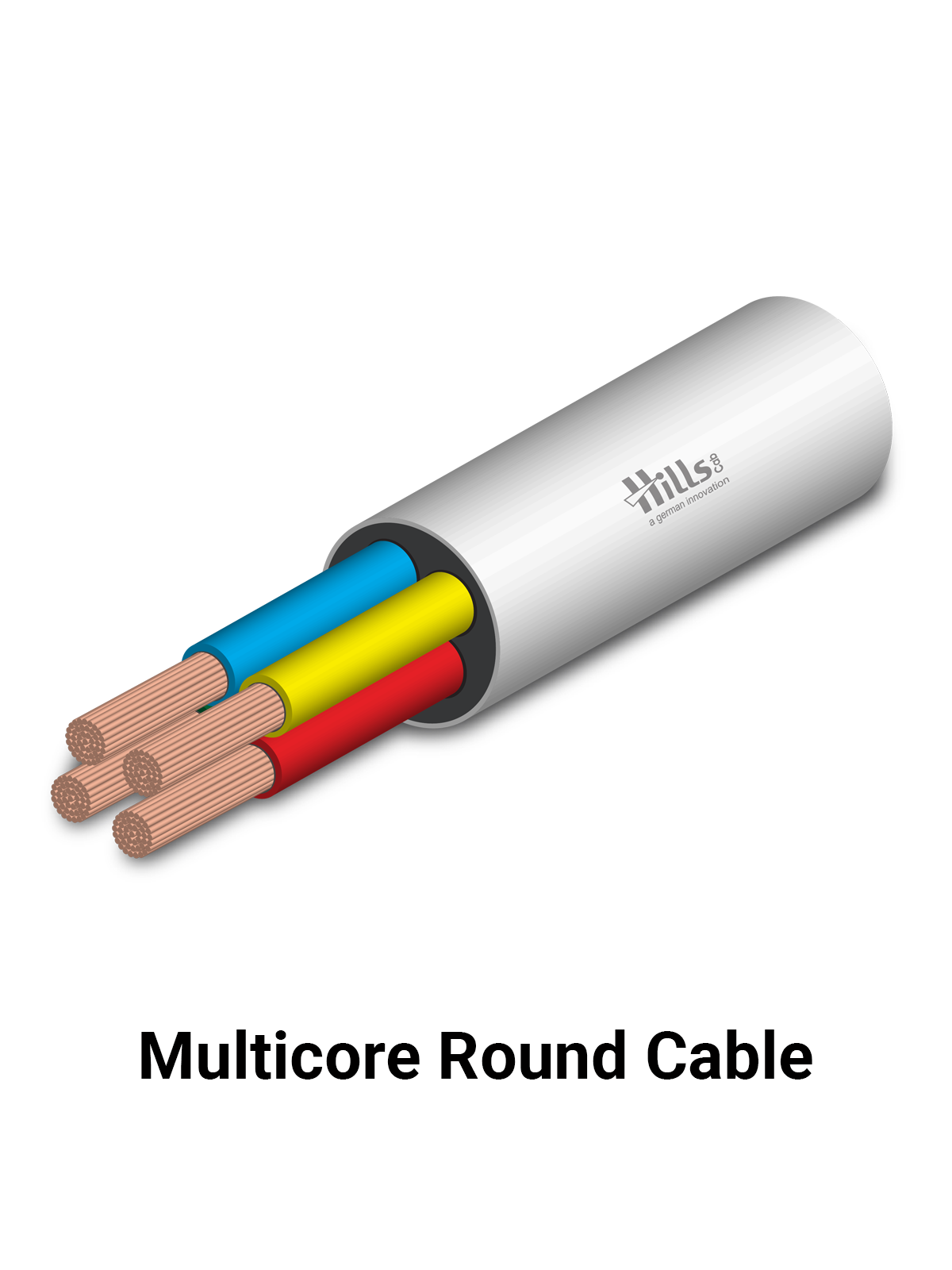

For over four decades, Hills Cab has lived up to the reputation of making reliable products that are designed to work efficiently and last a lifetime. A leading manufacturer of Wires and Cables since its inception, we augmented a wide range of products ranging from House wires (FR/FRLS/HRPVC/HRFR), Flexible Wires (Single & Multicore), PVC & XLPE Control Cables, PVC/ LOPE Instrumentation Cables, FRLS /FR/ HRFR/ HOFR /RUBBER/ LOPE Power Control & Instrumentation Cables, Low tension Copper / Aluminium conductor PVC & XLPE Power Cables, Dry & Jelly filled Telephone Cables, Railway Signaling Cables, Automobile Cables, Fire survival Halogen Cables.

Hills Cab also excels in making state-of-the-art Switch Gears, Switch Boards, Fans, MCBs, and Isolators among many of its manufactured accessories. We have consistently followed a growth path owing to our philosophy of constant product innovation and up-gradation. Always keeping up with modern times, Hills Cab proudly caters to the changing needs of the market. This has led to a fierce commitment to our customers, thereby delivering the best in terms of quality assuring their trust and confidence.

We pride ourselves on our ability to identify and satisfy customer needs through development of innovative products and unique, cost effective cable solutions for a wide range of industries. This and our extensive project experience make Hills Cab the supplier of choice for cable projects in the residential and commercial sectors.

We are also committed to comply with all applicable environments, health & safety legislation and all requirements of interested parties. Our commitment to the nation is to produce the best in quality and to ensure awareness among employees, society, interested parties about environment protection, minimization of waste, wise use of energy, water and other natural resources.

About Us

For over four decades, Hills Cab has lived up to the reputation of making reliable products that are designed to work efficiently and last a lifetime. A leading manufacturer of Wires and Cables since its inception, we augmented a wide range of products ranging from House wires (FR/FRLS/HRPVC/HRFR), Flexible Wires (Single & Multicore), PVC & XLPE Control Cables, PVC/ LOPE Instrumentation Cables, FRLS /FR/ HRFR/ HOFR /RUBBER/ LOPE Power Control & Instrumentation Cables, Low tension Copper / Aluminium conductor PVC & XLPE Power Cables, Dry & Jelly filled Telephone Cables, Railway Signaling Cables, Automobile Cables, Fire survival Halogen Cables.

Hills Cab also excels in making state-of-the-art Switch Gears, Switch Boards, Fans, MCBs, and Isolators among many of its manufactured accessories. We have consistently followed a growth path owing to our philosophy of constant product innovation and up-gradation. Always keeping up with modern times, Hills Cab proudly caters to the changing needs of the market. This has led to a fierce commitment to our customers, thereby delivering the best in terms of quality assuring their trust and confidence.

We pride ourselves on our ability to identify and satisfy customer needs through development of innovative products and unique, cost effective cable solutions for a wide range of industries. This and our extensive project experience make Hills Cab the supplier of choice for cable projects in the residential and commercial sectors.

We are also committed to comply with all applicable environments, health & safety legislation and all requirements of interested parties. Our commitment to the nation is to produce the best in quality and to ensure awareness among employees, society, interested parties about environment protection, minimization of waste, wise use of energy, water and other natural resources.

Manufacturing

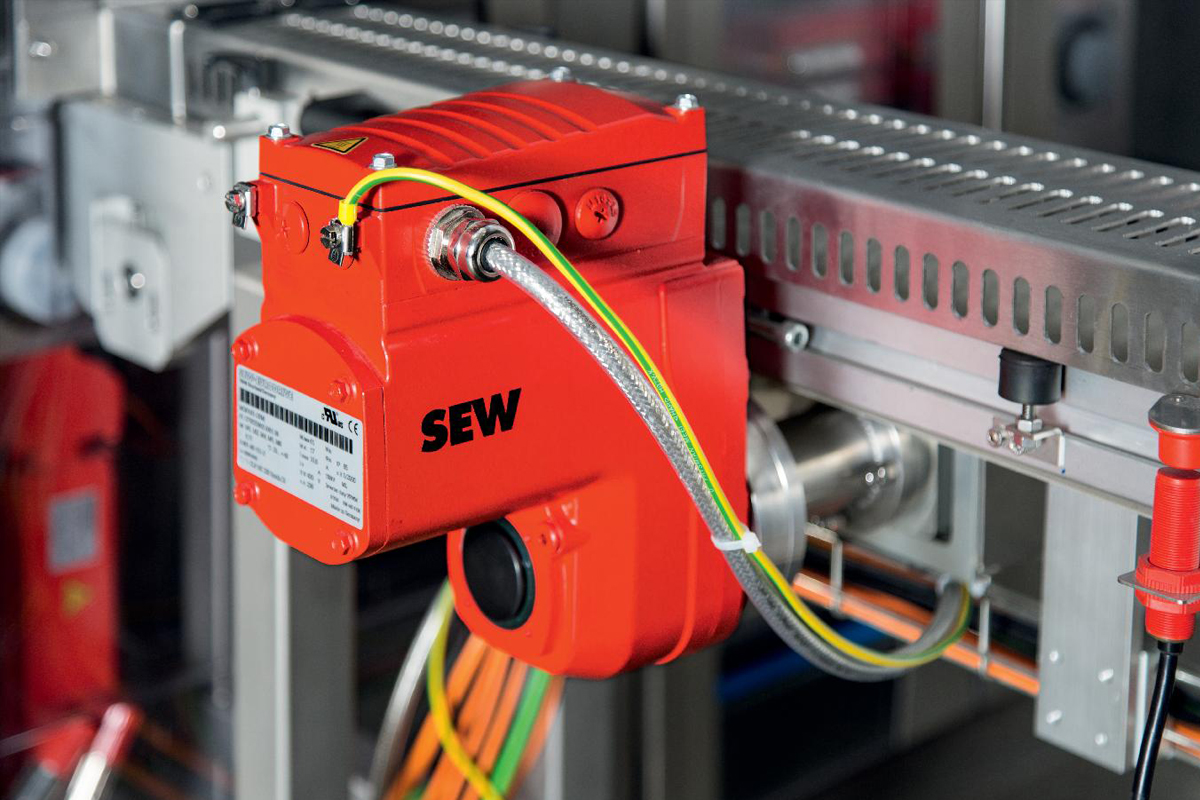

Our manufacturing facilities are located on Delhi, Uttarakhand, Ahmedabad with world class facilities and top class German machinery. We boast a state-of-the-art technology plant that is equipped with both indigenous and imported Machine Processes (RBD Wire drawing machines and bunchers by Niehoff | Triple Layer Insulating Lines by Nextrom, Johann Leimbach, etc).

The PVC Compounding unit is a fully automated modern plant established with the best manufacturing practices in mind. Right from the material handling to the end product, the best quality of the product is consistently assured in the safest environment possible. All raw materials of high quality used are derived from the best indigenous and imported sources contributing to the quality of Wires and Cables. This unit also boasts German machinery known for extrusion technology and a fully dedicated QA Lab.

Hills Cab strives to offer the best products to its customers. The company is approved by the Bureau of Indian Standards and all our products are certified with ISI mark. We are also Internationally approved by TCL and UKAS for ISO 9001:2008 certification.

Manufacturing

Our manufacturing facilities are located on Delhi, Uttarakhand, Ahmedabad with world class facilities and top class German machinery. We boast a state-of-the-art technology plant that is equipped with both indigenous and imported Machine Processes (RBD Wire drawing machines and bunchers by Niehoff | Triple Layer Insulating Lines by Nextrom, Johann Leimbach, etc).

The PVC Compounding unit is a fully automated modern plant established with the best manufacturing practices in mind. Right from the material handling to the end product, the best quality of the product is consistently assured in the safest environment possible. All raw materials of high quality used are derived from the best indigenous and imported sources contributing to the quality of Wires and Cables. This unit also boasts German machinery known for extrusion technology and a fully dedicated QA Lab.

Our Quality Objectives

We committed to continuous improvements to ensure the highest level of customer satisfaction

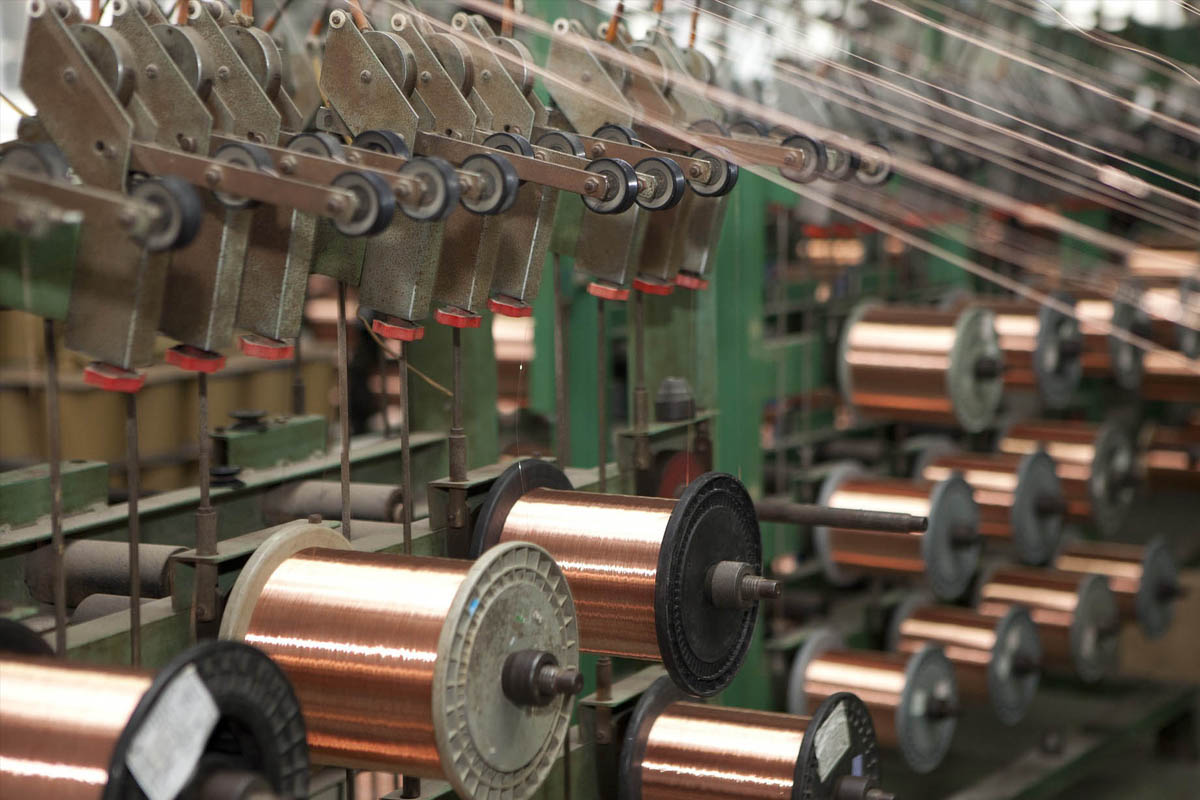

Wire Drawing

The copper, aluminium wire rods are drawn on high speed wire drawing machines having on-line annealing system. The annealing process acts as on-line inspector. The diameter of drawn wire is maintained in close tolerance.

Bunching

The fine drawn parallel wires undergo bunching operations on auto mode programmable logic controlling bunching machines ensuring even twisting and continuous 25 km smooth conductor.

Sheathing

Outer sheathing is carried out on extrusion lines with online diameter controllers, Inkjet Printing Machines and main extruder and dies. These extruders are used for PVC, Zero Halogen / Elastomeric compound and black LDPE for jacketing.

Armouring

Strip or Round wire armouring in GI, Copper or Aluminium is carried out on machines with synchronous drive system ensuring smooth and more than 90% coverage.

Quality Assurance

At Hillscab Plant, there is an inbuilt system adopted for quality assurance. It is consciously cultivated culture in the development and substance of which is involved a highly skilled and educated workforce guided by experienced and qualified engineers. We have complete in-house testing facilities for testing complete range of our production including testing facilities for FR/ FRLS/ FS properties.

Design of Product

The concept of product is evolved and introduced at the design stage itself. Customer’s requirement & specifications are studied by a well experienced & well qualified team of technocrats. Specifications are studied in detail & proper design is undertaken. The Company standards for design and raw materials have been set on the basis of Indian and International Specifications.

Our Quality Objectives

We committed to continuous improvements to ensure the highest level of customer satisfaction

Products

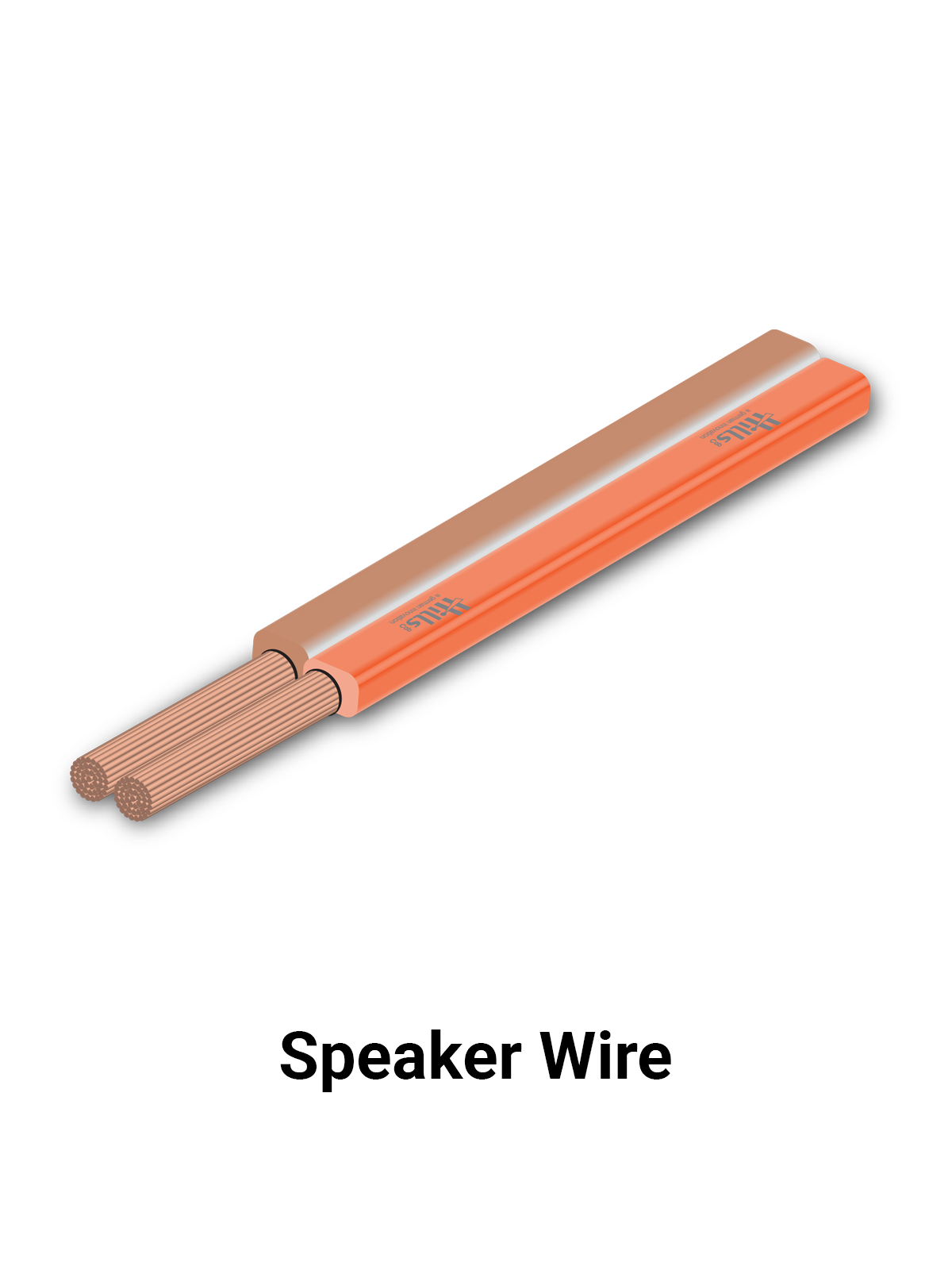

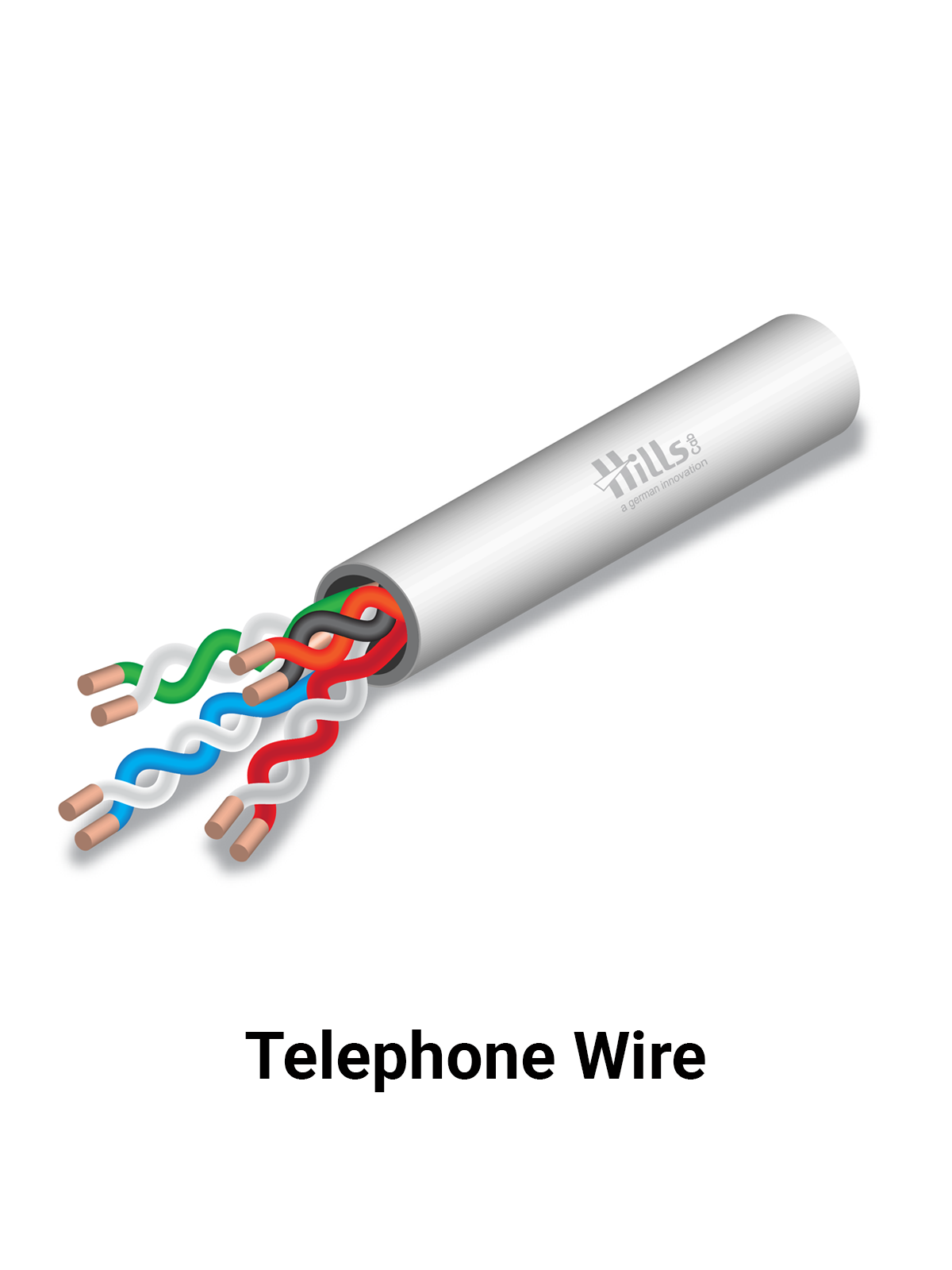

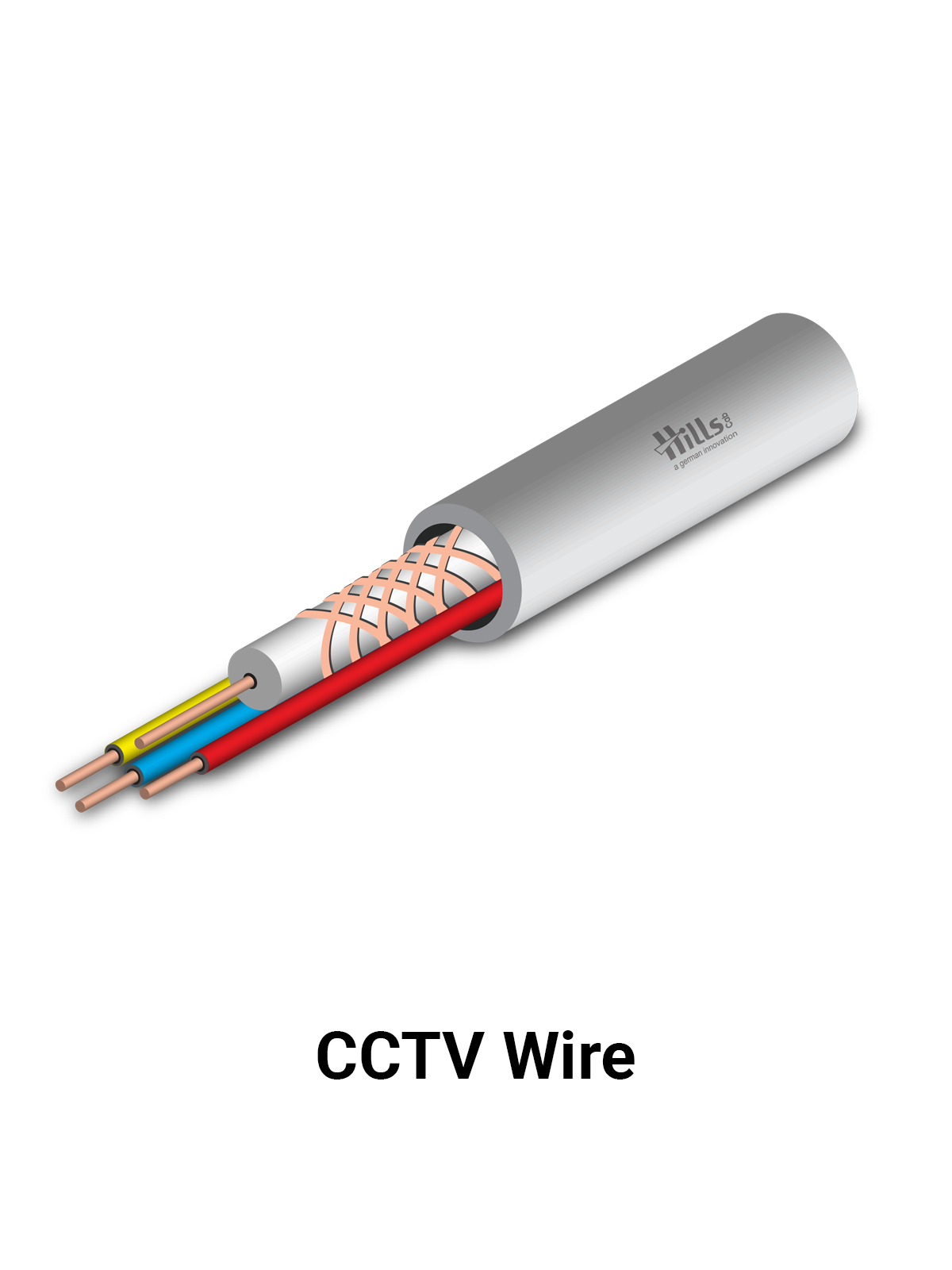

WIRES AND CABLES

Hills Cab, a trusted name among Wire and Cable Manufacturing company in India, understands this need and takes quality very seriously. Being among the leading wire manufacturers in India, all Hills Cab products are quality tested in their state-of-the-art facility. This ultra-modern and technologically advanced facility manufactures some of the best Heat Proof, Flame Proof and Rodent Proof Wires for all types of electronic applications.

HOME GUARD WIRES

HOME GUARD WIRES

COMMUNICATION WIRES

COMMUNICATION WIRES

INDUSTRIAL WIRES AND CABLES

INDUSTRIAL WIRES AND CABLES

AGRICULTURE WIRES

AGRICULTURE WIRES

Exterior & Interior Electrical Solutions

Our unblemished track record has earned us to patronage of leading Industrial Engineers & Architects

Exterior & Interior Electrical Solutions

Our unblemished track record has earned us to patronage of leading Industrial Engineers & Architects